Industrial Services

PGM Is Your Reliable And Qualified Partner For The Following Products and Market Fields:

Products

Maintenance Solutions

As a stabilized company operating in many countries, we provide all services for our customers as a service partner throughout the asset lifecycle. This includes everything from planning to coordination and execution of all maintenance work, to the application of digital solutions in maintaining industrial plants. We have consolidated our knowledge and experience as a maintenance partner for our customers in the PGM Maintenance Solution (PMS).

Turnaround solutions

Turnarounds on rotating equipment trains are always challenging projects. Short time schedules, complex products and high number of different suppliers require a professional project management. PGM supports you as a strategic business partner during this important phase. Our excellent field service network and qualified pool, as well as our extensive technical know-how and our certified project managers help you to successfully plan and execute large-scale turnarounds.

Inspection Solutions

With our PGM Solution, you receive an integrated and effective approach that merges multiple inspection services and support services, accessible via a unified interface. Our team of specialists, each with expertise in different fields, provides comprehensive support throughout the entire life cycle of your plant. This includes stages from prefabrication, through regular inspections during operation, all the way to dismantling, ensuring that all your varied inspection needs are met efficiently and effectively.

- NDT

- Material receiving Inspection

- 3D laser scanning

- Drone Inspection

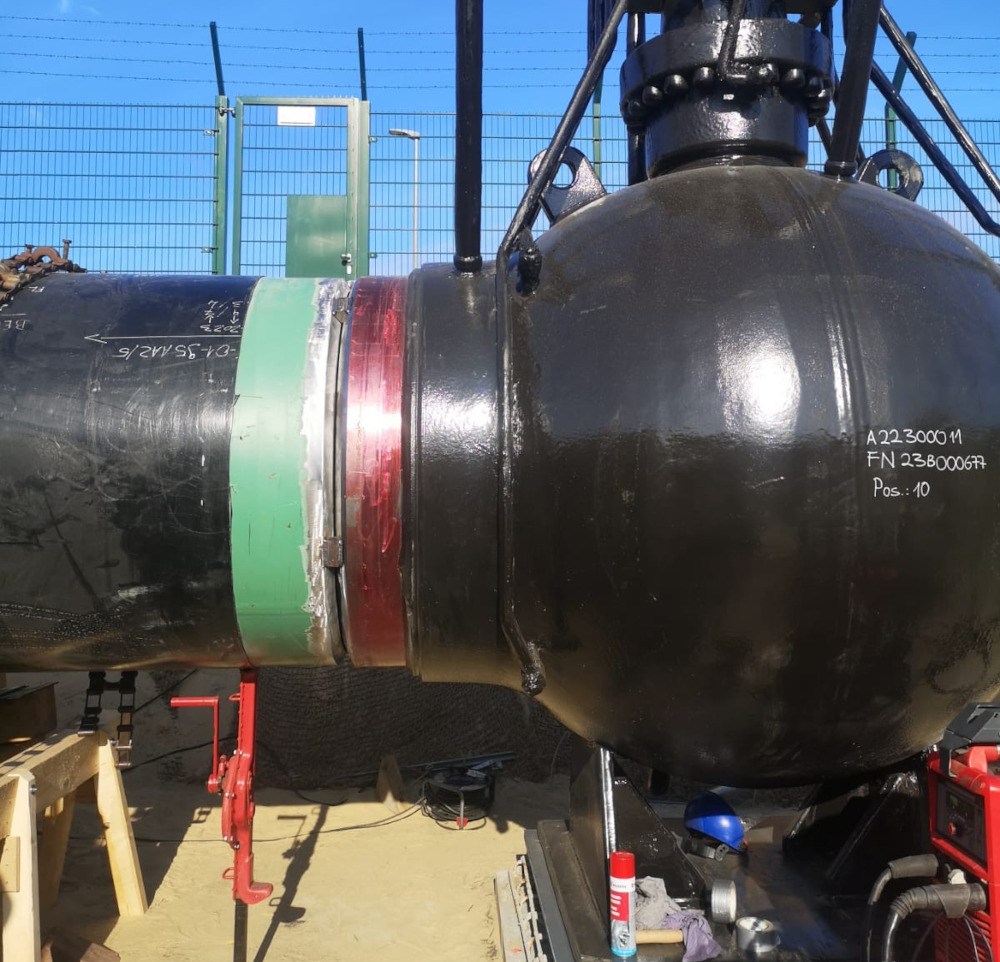

Full Welding solutions

Base materials, welding machine, consumables and more – many components contribute to perfect welding results. However, a Full Welding Solution by PGM is much more than the sum of its parts. We are recognized as in weld and metallurgy, and this is the solid trusted base on which our solutions are built. Our competent and committed specialists accompany the entire process and remain at the customer’s side until the work is done.

- Improved competitiveness due to higher productivity

- Industry-proven turnkey systems with perfectly coordinated components.

- Complete cost transparency for easier planning of your application challenges

- Our PGM Solution includes our own welding school, dedicated to transforming your welders into the best in their field.

Market Fields

- Power generation

- Wind farms "onshore & offshore"

- Hydrogen "green" plants

- Nuclear power including decommissioning.

- District heating

- Waste and biomass incineration

- Chemical and petrochemical industry

- Pulp and paper industry

- Steel industry

- Tank storage

- Food and beverage industry